In the summer of 2010, chef Colin Johnstone was cooking in the galley of the Janice Oil Production platform out in the North Sea. His old electric hotplates, although performing well, pumped out more heat into the kitchen than they did into the food. He contacted Control seeking a low-energy and more importantly less waste heat alternative.

In the summer of 2010, chef Colin Johnstone was cooking in the galley of the Janice Oil Production platform out in the North Sea. His old electric hotplates, although performing well, pumped out more heat into the kitchen than they did into the food. He contacted Control seeking a low-energy and more importantly less waste heat alternative.

Electric hot plates, traditional in marine catering equipment, are sturdy but very inefficient and very hot for the chef! Typically, less than 25% of the energy used by a commercial electric cooker ends up going into the food.

During the winter of 2010/2011, during a normal safety inspection, the safety officer along with an executive of Maersk Oil went into the galley on the Janice rig, which was very hot. As working in high temperatures reduces concentration and increases the chances of accidents, it was clear that an error in the kitchen had the potential to affect every member of the team on the rig. In short, the high ambient temperature in the kitchen could indirectly stop production on the oil rig.

As replacing the electric stoves became an important issue, an inspector was sent to the Control Induction factory to check the manufacturing methods, spare stocks, quality, reliability, etc. to ensure its suitability for supplying an oil rig. Following the factory inspection and agreement of specifications, two four-ring induction stoves (a total of 8 induction hobs) were ordered in the spring of 2011.

One unusual factor affecting the installation of these induction hobs was that Janice does not have a neutral available for high-power equipment. Control Induction quickly developed a system to convert the power removing this possible barrier.

One unusual factor affecting the installation of these induction hobs was that Janice does not have a neutral available for high-power equipment. Control Induction quickly developed a system to convert the power removing this possible barrier.

Following the installation, Control Induction contacted Colin Johnstone to check everything was working ok, his head chef said: "Yes they are great, the temperature of the galley is better now, thanks for your help and kind regards, Fab."

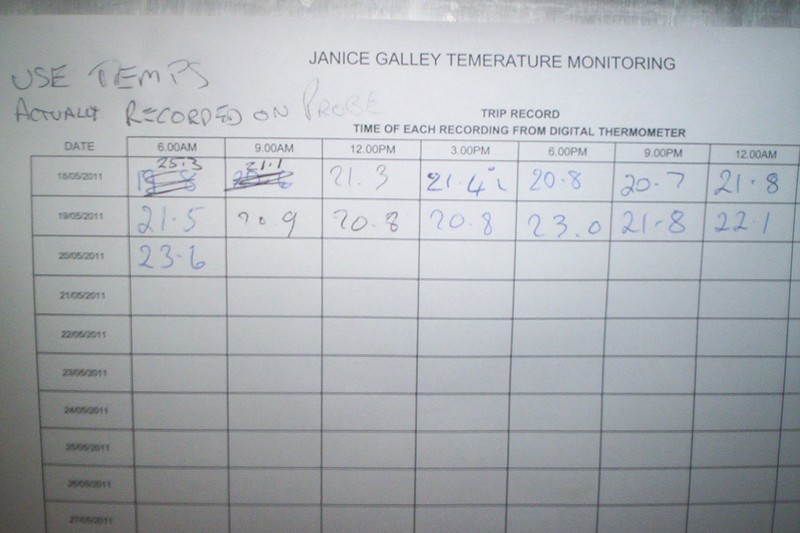

The figures below show very comfortable working temperatures in the galley, with the old electric hobs temperature in the galley regularly reaching 35-38°C.

"Just thought I would drop you a quick email to say that I and the team are enjoying cooking on our new stoves!! I know it took a while to get sorted out but eventually we did & I then ended up in the office for a few months so did not get out to use them until last week. They have had the desired effect and have reduced the overall temperature in our galley by approx. 5-8°C which is exactly what I thought they would, making our working environment much more comfortable for all of us. Additionally, they are far more efficient than our old stoves so lots of improvements from the chefs too haha. Once again many thanks for all your time & help getting the stoves made & out to us and I would not hesitate to recommend you to anyone in the future." - Chef Colin Johnstone's comments in August 2011